Results of Investing Activities

2012 witnessed the commissioning of 50 significant electric grid facilities.

LARGE AND TOP-PRIORITY FACILITIES COMMISSIONED IN 2012

| Item | Facility | Commissioned Capacity | Commissioning Date | |

|---|---|---|---|---|

| MVA | kilometers | |||

| MOESK | ||||

| 1. | SS 110 kV No. 836 Sloboda (phased commissioning) | 126 | 2Q | |

| 2. | Cable branch lines of OL 220 kV Omega–Radishchevo 1 and 2 to SS Sigma | 30.87 | 3Q | |

| 3. | SS 110 kV Sigma switched over to 220 kV | 500 | 3Q | |

| 4. | Cable branch lines of Cable OL 220 kV Beskudnikovo–CHPP-27 to SS Babushkin | 10.36 | 4Q | |

| 5. | SS 110 kV Polyanka with OL 110 kV branch lines | 50 | 1.03 | 4Q |

| 6. | SS 110 kV Babushkin switched over to 220 kV | 252 | 4Q | |

| 7. | OL 110 kV with changed branch lines to new Switchgear 110 kV of SS 750 kV Gribovo (Phase 1) | 25.45 | 4Q | |

| Tyumenenergo | ||||

| 8. | OL 110 kV Urengoy TPP–Urengoy with Switch Point 110 kV (Phase 1 as related to OL) (delivery of Urengoy TPP capacity) | 132.8 | 2Q | |

| 9. | OL 110 kV Igrim–Punga with SS 110 kV Punga | 20 | 111.2 | 3Q |

| 10. | OL 110 kV Oktyabrskaya–Peregrebnoye | 61.1 | 3Q | |

| 11. | OL 110 kV Sergino–Punga with SS 110 kV Sergino | 160.5 | 3Q | |

| 12. | OL 110 kV Kirillovskaya–Tavricheskaya | 163.5 | 4Q | |

| 13. | Expansion of Outdoor Switchgear 110 kV of SS Oktyabrskaya | 32.3 | 4Q | |

| 14. | SS 110 kV ABZ with main OL 110 kV | 50 | 38.0 | 4Q |

| IDGC of North-West | ||||

| 15. | Delivery of Vologda CHPP capacity (OL 110 kV SS Lugovaya–Distribution Substation 110 kV) | 2.98 | 1Q | |

| 16. | SS 110 kV Parfino | 32 | 3Q | |

| 17. | OL 110 kV SS 110 kV Sokolovka–SS 110 kV Pazhga | 25.3 | 4Q | |

| IDGC of Center and Volga Region | ||||

| 18. | SS 110 kV Rosva | 32 | 1Q | |

| 19. | SS Skopin (Phase 2) | 25 | 3Q | |

| 20. | SS 220 kV Sozvezdiye (Phase 2) | - | 3Q | |

| 21. | SS 110 kV Lizunovo | 10 | 4Q | |

| 22. | OL 110 kV Zvezda–Begichevo (Phase 2) | 7.6 | 4Q | |

| 23. | SS 110 kV Nikulinskaya | 50 | 4Q | |

| Kubanenergo | ||||

| 24. | SS 110 kV Matsesta | 40 | 1Q | |

| 25. | SS 110 kV Gelendzhik (Phase 2) | 40 | 4Q | |

| 26. | OL 110 kV Gostagaevskaya–Dzhemete | 16.96 | 4Q | |

| TDC | ||||

| 27. | SS 110 kV Moskovsky Trakt | 50 | 4Q | |

| LENENERGO | ||||

| 28. | CL 6–110 kV as related to CL 110 kV K-105 and K-106 | 8.3 | 4Q | |

| 29. | SS No. 185 Pushkin-Yuzhnaya | 80 | 4Q | |

| 30. | SS 110 kV No. 484 Ryabovo | 50 | 4Q | |

| IDGC of Centre | ||||

| 31. | OL 110 kV SS Plastmass–Livny CHPP (delivery of Livny CHPP capacity) | 4.51 | 1Q | |

| 32. | SS 110 kV Plastmass (delivery of Livny CHPP capacity) | - | 1Q | |

| 33. | SS 110 kV Bugor | 126 | 3Q | |

| 34. | SS 110 kV Sovetskaya (Phase 2) | 40 | 3Q | |

| IDGC of Volga | ||||

| 35. | OL 110 kV Kiembay–Priisk-Kumak–Svetly | 67.5 | 3Q | |

| 36. | SS 110 kV Erzya | 80 | 4Q | |

| 37. | Delivery of Novokuybyshevsk CHPP capacity | 23.6 | 4Q | |

| IDGC of Urals | ||||

| 38. | SS 110 kV Krasnopolskaya with OL 110 kV branch lines | 80 | 2.53 | 4Q |

| 39. | SS 110 kV Prirechnaya with OL 110 kV branch lines | 50 | 8.8 | 4Q |

| 40. | SS 110 kV Palniki with OL 110 kV branch lines | 80 | 2.53 | 4Q |

| IDGC of Northern Caucasus | ||||

| 41. | SS 110 kV Pump Station-4 (CPC) | 80 | 4Q | |

| IDGC of Siberia | ||||

| 42. | OL 110 kV Tom-Usinskaya TPP–Raspadskaya-5-1 | 52.6 | 2Q | |

| 43. | OL 110 kV Tom-Usinskaya TPP–Raspadskaya-5-2 | 52.1 | 2Q | |

| 44. | SS 110 kV Raspadskaya-4 | 80 | 2Q | |

| 45. | SS 110 kV Raspadskaya-5 | 32 | 2Q | |

| 46. | SS 110 kV Raspadskaya-6 | 80 | 2Q | |

| 47. | SS 110 kV Bystrinskaya | 32 | 4Q | |

| 48. | SS 110 kV Bugdainskaya | 32 | 4Q | |

| IDGC of South | ||||

| 49. | OL 110 kV SS Elista-Zapadnaya–SS Iki-Burul with branch lines | 85.2 | 4Q | |

| 50. | SS 110 kV Razvilka-2 | 80 | 4Q | |

In 2012, the Company implemented certain measures that were of substantial importance to passing the 2012/13 heat deficit period.

The following major projects included in the 2012 investment program deserve mentioning:

- Construction of OL 110 kV Sergino–Punga with the expansion of Outdoor Switchgear 110 kV Sergino (161 kilometers), Tyumenenergo;

- Construction of OL 110 kV Igrim–Punga with SS 110/6 kV Punga (20 MVA, 111 kilometers), Tyumenenergo;

- Rehabilitation of SS 110 kV No. 836 Sloboda (126 MVA), MOESK;

- Rehabilitation of SS 110/6 kV Sovetskaya (40 MVA), IDGC of Centre;

- Expansion of SS 110/35/6 kV Matsesta (40 MVA), Kubanenergo;

The investment programs of the Company subsidiaries for 2012 included the investment projects aimed at ensuring the delivery of capacity at 13 generators.

| Generation Company | Power Plant | Capacity Planned for Commissioning (MW) | The Company Subsidiaries |

|---|---|---|---|

| OGK-1 | Urengoy TPP | 450 MW | Tyumenenergo |

| Fortum | Tyumen CHPP-1 | 230.5 MW | Tyumenenergo |

| Fortum | Nyagan TPP (Units 1 and 3) | 2 x 418 MW | Tyumenenergo |

| Fortum | Tobolsk CHPP | 200 MW | Tyumenenergo |

| OGK-2 | Adler TPP | 360 MW | Kubanenergo |

| INTER RAO UES | Sochi TPP, Phase 2 | 80 MW | Kubanenergo |

| OGK-3 | Tuapse (Dzhubginskaya) TPP (Units 1 and 2) | 2 x 90 MW | Kubanenergo |

| TGK-2 | Kudepsta TPP | 360 MW | Kubanenergo |

| TGK-8 | Thsentralnaya boiler house, Astrakhan | 235 MW | IDGC of South |

| Volga TGK | Novokuybyshevsk CHPP-1 | 240 MW | IDGC of Volga |

| Kvadra | Livny CHPP | 30 MW | IDGC of Centre |

| TGK-2 | Vologda CHPP | 110 MW | IDGC of North-West |

| TGK-9 | Perm CHPP-9 | 165 MW | IDGC of Urals |

The following facilities were completed in 2012:

- Vologda CHPP,

- Livny CHPP,

- Urengoy TPP,

- Novokuybyshevsk CHPP-1,

- Nyagan TPP.

Work on the other facilities was performed in accordance with the 2012 investment program.

MOESK

New construction

In the 3rd quarter of 2012, the construction of cable branch lines of OL 220 kV Omega–Radishchevo 1 and 2 to SS Sigma was completed. 30.87 kilometers were commissioned. Work on this project will make it possible to solve the electric capacity shortage and redress imbalances in the construction of infrastructural and electric facilities and will provide opportunities for new network connections.

In the 4th quarter of 2012, the construction of SS 220/110/10 kV Sigma was completed, which one of Moscow’s largest main substations. 500 MVA were commissioned. The construction used state-of-the-art equipment: Siemens-made 220/110-kV SF6-insulated factory-assembled switchgear; two 220/110/10-kV autotransformers, 250 MVA each; four regulating transformer, 63 MVA each; new 10-kV factory-assembled switchgear composed of 8 sections and designed for 72 cubicles. On a centralized basis, the substation supplies electricity to production facilities and public and residential buildings in Moscow’s Zelenograd Administrative District. In addition to making the existing electricity supply more reliable, one of the principal objectives of the substation rehabilitation, which involved switching over to 220 kV, is to offer network connection opportunities to new customers, which are mainly residents of the Zelenograd Special Economic Zone.

In the 4th quarter of 2012, the construction of cable branch lines of Cable OL 220 kV Beskudnikovo–CHPP-27 to SS Babushkin was completed. 10.36 kilometers were commissioned. The decision to build the new cable line was made in accordance with Resolution of the Government of Moscow No. 808-PP of August 25, 2009, “On the Implementation of Investment Programs for the Construction and Rehabilitation of Power Facilities.” Additionally, the cable line is included in Law of Moscow No. 33 of July 5, 2006, “On the Comprehensive Development Program for the Moscow Electricity Supply System for 2006–2010 and the Investment Programs for the Development and Modernization of the City’s Electricity Supply Infrastructure.” The cable line is located in Moscow’s Northeastern Administrative District. The construction included Cable OL 220 kV CHPP-27–Babushkin and Cable OL 220 kV Beskudnikovo–Babushkin, using the 2XS(FL)2Y-LWL 1x2000RMS/310-127/220-kV polyethylene-insulated cable. The switch point is equipped with OTC-245OF cable terminals while SS Babushkin is equipped with 220-kV SF6-insulated factory-assembled switchgear; the cable line is connected to the SF6-insulated factory-assembled switchgear through an SF6-insulated EHSVS-245OF bushing. Work on the project made it possible to rehabilitate SS 110/10/6 kV Babushkin with switching over to 220 kV, and develop and modernize Moscow’s electricity supply infrastructure.

In the 4th quarter of 2012, the construction of SS 110/10 kV Pobeda (Polyanka dispatching administration) 2 x 25 MVA with OL 110 kV branch lines was completed. The project implementation aimed to supply electricity to the Russian Housing Development Foundation’s residential estate located in the Istra District, Moscow Region. 50 MVA and 1.03 kilometers were commissioned. The project implementation used the project-based management method as part of implementing the Construction Management System for Major Investment Projects.

Technical upgrading and rehabilitation

In the 2nd quarter of 2012, the rehabilitation of SS 220 kV Sloboda (Phase 3) was completed. The following equipment was rehabilitated and included in fixed assets: two transformers, 63 MVA each; four groups of line reactors rated 6–10 kV; two booster transformers, 40 MVA each. The rehabilitation involved providing new SF6-insulated factory-assembled switchgear for Cable OL 110 kV Sloboda–Dedovo and Sloboda–Nakhabino. The decision to rehabilitate the substation was made as part of fulfilling the agreement between RAO UES of Russia and the Moscow Region Government to enhance the reliability of the electricity supply for customers in the Moscow Region. The substation has an extremely important role in the system of delivering capacity from a new power unit of Kalinin NPP to the 220/110-kV network and is a new supporting main substation for the electricity supply for customers in the Istra District, the Zvenigorod District, and part of the Krasnogorsk District of the Moscow Region. The substation rehabilitation involved switching over to 220 kV with the installation of 220/110-kV SF6-insulated factory-assembled switchgear and two autotransformers, 250 MVA each, and with the construction of new 10-kV factory-assembled switchgear. Work on the substation rehabilitation made it possible to secure a reliable electricity supply and satisfy the growing demand of the Moscow Region’s economic entities.

For the delivery of capacity from Unit 4, the rehabilitation of OL 110 kV with changed branch lines to new Switchgear 110 kV of SS 750 kV Gribovo (Phase 1) was completed at Kalinin NPP in the 4th quarter of 2012. 25.45 kilometers were commissioned. The decision to rehabilitate the overhead line was made pursuant to Resolutions of the Government of the Russian Federation No. 605 of October 6, 2006, and No. 705 of September 20, 2008. In accordance with Instructions of the Prime Minister of the Russian Federation No. VP-P7-2167 of April 6, 2010, FGC UES started building the facilities designed to deliver capacity from Unit 4 of Kalinin NPP, and MOESK is engaged in work to provide Rosenergoatom Concern electrical installations with connection to FGC UES electric grids in accordance with the Specifications of February 11, 2011 (as amended). The rehabilitated overhead lines pass through the Volokolamsk District, Moscow Region. The rehabilitation of the above-mentioned 110-kV overhead lines ensured transmission capacity of 900 A. Overall, the reliable electricity supply for the Moscow Region is a precondition for economic growth. The project implementation aims to secure a more reliable electricity supply for all categories of customers, improve the quality of delivered electricity, reduce electricity losses, and achieve a positive social effect.

In the 4th quarter of 2012 the rehabilitation of SS 110/10/6 kV Babushkin with switching over to 220 kV and installing indoor equipment was completed. The following equipment was installed at the substation: four 220/10-kV transformers, 63 MVA each, and two 10/6-kV transformer units, 16 MVA each. 220-kV SF6-insulated factory-assembled switchgear has two operating busbar systems designed for connection of two 220-kV lines, four transformers, and a busbar coupler. The device incorporates two backup cubicles. New 10-kV indoor switchgear was installed. It is designed for 64 single-cable line cubicles and four-section indoor switchgear rated 6 kV, which is sufficient to decommission the old factory-assembled outdoor switchgear rated 6 kV. This resulted in securing a reliable and uninterrupted power supply for Moscow’s Northeastern Administrative District. The decision to rehabilitate the substation was made pursuant to Law of Moscow No. 44 of October 20, 2010, “On Amendments to Law of Moscow No. 33 of July 5, 2006, ‘On the Comprehensive Development Program for the Moscow Electricity Supply System for 2006–2010 and the Investment Programs for the Development and Modernization of the City’s Electricity Supply Infrastructure.’” This facility is one of Moscow’s head-end main substations. Work on the substation rehabilitation made it possible to secure a reliable electricity supply and satisfy the growing demand of Moscow.

TYUMENENERGO

New construction

In the 2nd quarter of 2012, the construction of 132.885-kilometer OL 110 kV (Phase 1) as part of OL 110 kV Urengoy TPP–Urengoy with Switch Point 110 kV at the village of Limbya-Yakha with OL 110 kV branch lines was completed. Currently, electricity is supplied to customers located in Limbya-Yakha via existing OL 110 kV (designed for 220 kV) SS 220/110 kV Urengoy–SS 110 kV Industrial Site. Due to the construction of Urengoy TPP, the overhead line was switched over to its rated voltage and began to be used for the delivery of Urengoy TPP capacity. To replace this overhead line for the purpose of supplying electricity to local customers, design work continues on double-circuit OL 110 kV SS 220/110 kV Urengoy–Switch Point 110 kV Limbya-Yakha. The project implementation will make it possible to connect existing customers to new OL 110 kV and ensure the delivery of Urengoy TPP capacity.

In the 3rd quarter of 2012, the construction of OL 110 kV Igrim–Punga with SS 110/6 kV Punga was completed. 111.2 kilometers (2 x 55.6 kilometers) and 20 MVA were commissioned. The OL 110 kV route crossed an overhead line rated 6–10 kV, automobile roads and winter roads, underground gas and condensate pipelines, rivers, streams, lakes, and a navigable waterway. The principal goal of the project is to create electric power infrastructure for the effective industrial realization of the mineral and raw material potential of the subarctic regions of the Urals and provide a centralized electricity supply for such settlements in the Beryozovo District as Svetly, Igrim, Beryozovo, Vanzitur, and Shaytanka. The Beryozovo power center has not had a centralized electricity supply, and electricity has been supplied to its customers from separate power plants owned by different companies.

In the 3rd quarter of 2012, the construction of OL 110 kV Sergino–Punga with the expansion of Outdoor Switchgear 110 kV Sergino was completed. 160.5 kilometers (2 x 80.25 kilometers) were commissioned. The principal goal of the project is to secure an uninterrupted and high-quality electricity supply for existing household customers residing in Punga, Aneeva, Sartynya, Sosva, Lombovozh, and Saranpaul and industrial customers located in the subarctic regions of the Urals and create conditions for the further development of both industrial production and centers of population.

In the 3rd quarter of 2012, the construction of OL 110 kV Oktyabrskaya–Peregrebnoye was completed. 61.1 kilometers were commissioned. The construction of the new overhead line made it possible to reinforce the network supplying electricity to industrial and household customers, ensure the operating reliability of the 110-kV network in the Oktyabrskoye and Beloyarsky Districts, and increase reserve capacity for repairs and postemergency conditions.

In the 4th quarter of 2012, the construction of SS 110 kV ABZ with main OL 110 kV was completed. 50 MVA and 38.0 kilometers were commissioned. The project implementation resulted in building 38.006-kilometer main OL 110 kV, constructing SS 110 kV with the installation of two transformers, 25 MVA each. The principal goal of the construction is to secure a reliable electricity supply for Khanty-Mansijsk.

In the 4th quarter of 2012, the construction of OL 110 kV Kirillovskaya–Tavricheskaya was completed. 163.52 kilometers (2 x 81.76 kilometers) were commissioned. The project was carried out pursuant to Law of the Khanty-Mansijsk Autonomous District – Yugra No. 103-oz of July 20, 2007, on the 2007–2015 Program “Centralized Electricity Supply for Centers of Population in the Khanty-Mansijsk Autonomous District – Yugra.” In order to reinforce the 110-kV Kirillovskaya–Tavricheskaya network, double-circuit OL 110 kV Kirillovskaya–Tavricheskaya (3, 4 circuits) was built, using double-circuit dead-end OL 110 kV Tavricheskaya–Povkhovskaya. The project implementation made it possible to avert overloads in periods of peak demand in the winter, increase transmission capacity, and offer connection opportunities for new customers located in the Kirillovskaya–Tavricheskaya area.

In the 4th quarter of 2012, the expansion of Outdoor Switchgear 110 kV of SS 110 kV Oktyabrskaya was completed. The project implementation aims to enhance the reliability of the electricity supply for customers located in the Oktyabrskoye and Beloyarsky Districts, raise net delivery, improve the quality of the electricity supply, reinforce the electricity supply for main gas pipelines, households, and small industrial customers, and provide a centralized electricity supply for centers of population located on the right bank of the Ob River. The construction resulted in building a 16.16-kilometer double-circuit section of OL 110 kV, adding two cubicles to Outdoor Switchgear 110 kV Oktyabrskaya, erecting a new building of the general substation control point, and altering the transformer group due to changes in the main electric circuit. The project implementation used the project-based management method as part of implementing the Construction Management System for Major Investment Projects.

IDGC OF NORTH-WEST

New construction

In the 4th quarter of 2012, work on Phase 1 of the construction of OL 110 kV Sokolovka–Pazhga with the expansion of SS 110/10 kV Sokolovka and SS 110/10 kV Pazhga was completed. The project implementation resulted in building double-circuit 110-kV overhead lines with a total length of 24.9 kilometers and a single-circuit 110-kV overhead line with a length of 0.4 kilometer. Work on Phase 1 made it possible to provide connection for the Finno-Ugric Ethnic Culture Park and secure a reliable electricity supply for customers located in the Sysolsky, Priluzsky, and Koygorodok Districts in the Komi Republic. The project implementation used the project-based management method as part of implementing the Construction Management System for Major Investment Projects.

Technical upgrading and rehabilitation

In the 1st quarter of 2012, the Vologdaenergo Branch completed Phase 2 of the rehabilitation of OL 110 kV in the SS 110 kV Lugovaya section with branch lines to Distribution Substation 110 kV under the project of the construction of Distribution Substation 110 kV and the rehabilitation of OL 110 kV in the SS 110 kV Lugovaya section with branch lines to Distribution Substation 110 kV. The project is carried out as part of providing connection for a unit of CCGT-110 of Vologda CHPP (TGK-2). In the rehabilitated section of OL 110 kV, the AS wire was replaced by the ASSR300-T16 composite aluminum wire, which made it possible to substantially increase the transmission capacity of OL 110 kV. 2.984 kilometers were commissioned.

In the 3rd quarter of 2012, SS 110 kV Parfino was put into operation after complete rehabilitation in the village of Parfino. The substation rehabilitation began in 2011 and consisted of two phases. In 2011, existing utility systems were moved away from the construction site, and the first supply transformer was installed. In 2012, the second transformer was installed on the construction site, and work was done on the installation of 110-kV outdoor switchgear, relay protection, telecontrol, and communication systems. The substation is equipped with two transformers, MVA each; Siemens-made switching equipment; modern cubicles rated 6 and 10 kV; and equipment protection and data transmission devices. The operation of the power center is monitored by computer-aided controls from a control room on the premises of the substation. Starting from 2008, SS 110 kV Parfino had been a main substation with limited capabilities. Its previously installed capacity of supply transformers (10 and 6.3 MVA) had prevented it from providing network connections for any new customers or increasing electricity delivery to existing customers. It had not been possible to release the load of either transformer in periods of peak demand in the fall and winter.

IDGC OF CENTER AND VOLGA REGION»

New construction

In the 3rd quarter of 2012, the construction of SS 220 kV Sozvezdiye (Phase 2) was completed. The construction of SS 220/110/10 kV Sozvezdiye follows recommendations contained in the long-term development program for the Kaluga Region electric power industry until 2015 with long-term plans until 2020 as approved by the ordinance of the Kaluga Region Government. The project implementation aims to secure an uninterrupted electricity supply for residents of the Vorsino industrial park and enhance the reliability of the Obninskoye power center. The substation is located in the Borovsk District, Kaluga Region. The project implementation used the project-based management method as part of implementing the Construction Management System for Major Investment Projects.

In the 4th quarter of 2012, work on Phase 1 of SS 110/6 kV Lizunovo was completed under the project to build SS 110 kV 2 x 10 MVA (Phases 1 and 2). 10 MVA were commissioned, with the plan of 10 MVA for 2012. The project implementation aims to secure a more reliable electricity supply and offer connection opportunities to new customers. The following work was done in 2012: design and estimate documents were prepared; a land lease agreement was signed; a building permit was obtained; a contract agreement for construction and installation was signed; a temporary access road, substation fencing, temporary electricity supply, foundation, and building frame were provided for the general substation control point; a building was erected for the general substation control point and indoor switchgear; foundations were laid for Outdoor Switchgear 110 kV; fit-out work was completed in the general substation control point and indoor switchgear; two TDN-10000/110 transformers were installed; six portals were installed; piping was provided; equipment was purchased and installed for Outdoor Switchgear 110 kV in Phase 2; equipment was installed for the general substation control point; busbars were provided for Outdoor Switchgear 110 kV; precommissioning was done in Phase 1.

Technical upgrading and rehabilitation

In the 1st quarter of 2012, the rehabilitation of SS 110 kV Rosva with the replacement of 110-kV transformers and switching over to 220 kV (Phase 1) was completed. Commissioned transformer capacity totaled 32 MVA due to the installation of two 110-kV transformers, 16 MVA each. The decision to rehabilitate the substation was made because it was necessary to provide new customers with connections to the Kalugaenergo Branch’s network and carry out measures under the long-term development program for the Kaluga Region electric power industry until 2015 with long-term plans until 2020 as approved by the ordinance of the Kaluga Region Government. Putting Phase 1 into operation provided additional growth opportunities for the region’s biggest technology park, Rosva, specifically a Peugeot Citroёn factory and a private industrial park of Lemminkainen Group, Finland. In addition, putting the substation into operation will enhance the overall reliability of Kaluga’s electricity supply.

In the 3rd quarter of 2012, the rehabilitation of SS 110 kV Skopin (Phase 2) was completed, with transformer capacity of 25 MVA commissioned as a result of replacing a 20-MVA transformer by a 25-MVA transformer. The decision to rehabilitate substation was made as part of fulfilling the agreement between the Ryazan Region Government and RAO UES of Russia concerning the development of the Ryazan Region electric power sector, carrying out the 2012–2017 Ryazan Region Electric Power Industry Development Program approved by Ordinance of the Ryazan Region Government No. 203-r of May 16, 2012, due to the necessity of replacing the equipment that was in operation from 1954. Located in the town of Skopin, Ryazan Region, SS Skopin is a main substation supplying electricity to Skopin (a population of more than 30,000) and most customers in the Skopin Municipal District.

In the 4th quarter of 2012, the rehabilitation of SS 110/35/10 kV Nikulinskaya was completed. 50 MVA were commissioned. The rehabilitation aims to reduce equipment maintenance and repair costs and enhance the reliability and quality of the electricity supply for customers located in Aleksin (the main customers are Aleksinstroyinvest, NOK, Nik-Universal, and the Tula Division of Russian Railways).

In the 4th quarter of 2012, the rehabilitation of OL 110 kV Zvezda–Begichevo with a branch line and OL 110 kV Zvezda–Volovo (Phase 2) was completed. The principal objective of the project was to increase the transmission capacity of electricity networks, enhance the reliability and quality of the electricity supply for customers located in the Yefremov, Volovo, Kamensky, and Kurkino Districts, and raise the reliability of 110-kV transit between the Novomoskovsk and Yefremov power centers. 7.6 kilometers were commissioned. The project implementation used the project-based management method as part of implementing the Construction Management System for Major Investment Projects.

KUBANENERGO

Technical upgrading and rehabilitation

In the 2nd quarter of 2012, the Sochi Electricity Networks completed the expansion of SS 110 kV Matsesta with the installation of 40-MVA T-3 transformers. Transformer capacity of 40 MVA was commissioned. The substation expansion was in accordance with Agreement No. 20206-10-00007254-2 of May 7, 2010, with North Caucasian Railway, a branch of Russian Railways, to provide network connections for SS 35/3.3 kV Matsesta-Tyagovaya.

In the 4th quarter of 2012, the rehabilitation of SS 110 kV Gelendzhik (Phase 2) was completed. Transformer capacity of 80 MVA was commissioned. In order to provide network connections for new customers located in the resort town of Gelendzhik, one T-1 transformer rated 25 MVA at the substation was replaced by a 40-MVA transformer, and a T-3 transformer rated 40 MVA was installed. The project implementation used the project-based management method as part of implementing the Construction Management System for Major Investment Projects.

In the 4th quarter of 2012, the construction of 16.96-kilometer OL 110 kV Gostagaevskaya–Dzhemete was completed, with the installation of 119 towers, including 99 tangent-suspension towers and 20 angle-tension towers. The rehabilitated 110-kV overhead line connects the village of Gostagaevskaya to the resort town of Anapa. A commissioning certificate was issued, and the overhead line was included in the fixed assets of the Southwest Electricity Networks.

TDC

New construction

In the 4th quarter of 2012, SS 110 kV Moskovsky Trakt with 110-kV power line branch lines was put into operation. 50 MVA were commissioned. The substation construction is specified in TDC’s program to develop the network rated 35–110 kV with the aim of optimizing the operating condition of the Yuzhnaya–TIZ–CHPP-1 power center and enhancing the quality of supplied electricity. This substation will supply electricity to some customers of the existing 35-kV substations Yuzhnaya and TIZ, which are currently overloaded, and will be used to back up loads from CHPP-1. The project implementation made it possible to secure a reliable electricity supply for a cancer detection center, a municipal hospital, a municipal water-pumping plant, and other facilities. The project implementation used the project-based management method as part of implementing the Construction Management System for Major Investment Projects.

LENENERGO

New construction

In the 4th quarter of 2012, the renewal of CL 6–110 kV was completed as related to CL 110 kV K-105 and K-106 with a length of 8.3 kilometers. The renewal of 110-kV cable lines increased the transmission capacity of power lines, secured a more reliable electricity supply for customers located in Saint Petersburg’s Central and Krasnogvardeysky Districts, including Category 1 customers and socially important facilities, and created conditions for connecting additional loads. The project implementation used the project-based management method as part of implementing the Construction Management System for Major Investment Projects.

Technical upgrading and rehabilitation

In the 4th quarter of 2012, the rehabilitation of SS No. 185 Pushkin-Yuzhnaya was completed. The second supply transformer rated 80 MVA was put into operation. The Pushkin-Yuzhnaya substation is the mainstay of Pushkin’s power supply. The substation was extensively upgraded: new 110-kV SF6-insulated factory-assembled switchgear was built; indoor switchgear rated 6 and 10 kV and line reactors were installed. A new general substation control point was constructed. Additionally, the new transformers enabled the substation’s capacity to be doubled to 160 MVA. The completed measures make it possible to provide permanent network connections for a military town and new customers.

In the 4th quarter of 2012, the rehabilitation of SS 110 kV No. 484 Ryabovo was completed. Two 16-MVA transformers were replaced ahead of schedule by two 25-MVA transformers. The substation rehabilitation will make it possible to provide full capacity for Gazstroy and Ryabovo Ceramics Factory and provide network connections for new customers.

IDGC OF CENTRE

New construction

One of the most significant and largest projects of IDGC of Centre’s capital investment program is the project of the delivery of Livny CHPP capacity. The goal of the project is to ensure the delivery of capacity from the 31.5-MW gas turbine unit (GTU) installed at Livny CHPP to the electricity network of the Oryolenergo Branch as requested by the Kvadra generation company under the existing network connection contract. Under the project, the 110-kV Plastmass substation was rehabilitated and a 110-kV power line was built.

The rehabilitation involved switching the substation over to the 4-N configuration (two units with disconnecting switches and a nonautomatic main switch on the side of lines), dismantling the old 110-kV outdoor switchgear, replacing 110-kV isolator switches and short-circuiters by 110-kV SF6 switches, installing busbar systems for 110-kV outdoor switchgear, installing 110-kV current transformers in 110-kV SF6 switch circuits. In addition, work was performed on installing modern microprocessor-based protection and equipment for direct control current at the substation.

The 110-kV power line consists of two sections: a 110-kV overhead power line with a length of 3.53 kilometers and a 110-kV cable power line with a length of 0.98 kilometer built using the horizontal directional drilling method within the town of Livny.

In addition to the delivery of Livny CHPP capacity, the project implementation secured a reliable electricity supply and created conditions for providing customers with network connections in the Oryol Region.

Technical upgrading and rehabilitation

In the 3rd quarter of 2012, the rehabilitation of SS 110/35/6 kV Bugor was completed, with 126 MVA of transformer capacity commissioned as a result of replacing two 15-MVA transformers and one 25-MVA transformer by two transformers, 63 MVA each. The substation’s capacity addition eventually totaled 71 MVA. The decision to rehabilitate substation was made in accordance with the program to develop the Lipetsk energy system’s electricity networks rated 35–110 kV for 2010 with long-term plans until 2015 (due to the necessity of replacing equipment that had been in operation from 1961). The substation is the main supplier of electricity for the city’s central part. The substation uses modern equipment:

- Outdoor switchgear rated 110 kV.

- Microprocessor-based relay protection.

- Equipment of the Automated Information System of Electricity Billing Metering and the Automated Dispatching System (installation is underway).

The project implementation made it possible to:

- Create sufficient capacity for putting into operation new infrastructural and utility facilities in Lipetsk.

- Solve the electric capacity shortage in the central part of Lipetsk.

- Enhance the reliability of the electricity supply for existing customers.

- Create conditions for the rehabilitation, modernization, and high-quality repair of equipment used by existing substations.

The project implementation used the project-based management method as part of implementing the Construction Management System for Major Investment Projects.

In the 3rd quarter of 2012, the rehabilitation of SS 110/6 kV Sovetskaya was completed, with 80 MVA of transformer capacity commissioned (40 MVA commissioned in 2012) as a result of replacing two 16-MVA transformers and one 25-MVA transformer by two transformers, 40 MVA each. The substation’s capacity addition eventually totaled 23 MVA. The decision to rehabilitate substation was made at a joint meeting held on March 28, 2005, and dealing with the electricity supply for the central and northwest parts of Bryansk’s Sovetsky District (due to the necessity of replacing equipment that had been in operation from 1964). The substation is the head-end main substation in the central and northwest parts of Bryansk’s Sovetsky District. The substation uses modern domestic equipment:

- Outdoor switchgear rated 110 kV with one busbar system sectionalized by a switch. This is factory-assembled outdoor switchgear with a 110-kV unit-type package transformer substation made by Electroshield – TM Samara;

- Indoor switchgear rated 6 kV with two single busbar systems sectionalized by switches. This is K-63/K-61M 6-kV factory-assembled switchgear made by Electroshield – TM Samara.

In order to improve the quality of electric power and with due consideration to the long-term development of the substation, each section of the 6-kV indoor switchgear will incorporate reactive power compensators, namely KRM-6.3-1800 controllable capacitor banks.

The substation is equipped with two direct current switchgear units made by Tekhnokomplekt, Dubna. Relay protection is microprocessor-based equipment made by EKRA and Radius Avtomatika.

Work is underway to install equipment of the Automated Information System of Electricity Billing Metering and the Automated Dispatching System. Work on the substation rehabilitation made it possible to secure a reliable electricity supply and satisfy the growing demand of new facilities (it is planned to construct about 27 socially important facilities and residential and public buildings in the center of Bryansk’s Sovetsky District by 2015).

IDGC OF VOLGA

New construction

In the 3rd quarter of 2012, work was completed on OL 110 kV Kiembay–Priisk-Kumak–Svetly, replacing the existing overhead line (Phase 2) (new construction). The project’s goals and objectives are as follows: enhancing the reliability of the electricity supply for SS 110/35/6 kV Svetlinskaya supplying electricity to two SS 110 kV and six SS 35/10 kV of the Svetly District, Buruktalsky Steel Works, and Buruktalskoye Mine. The transmission capacity of new OL 110 kV allowed industrial customer located in the Svetly and Adamovka Districts, Orenburg Region, to increase their loads. 67.47 kilometers were commissioned (Phase 2).

In the 4th quarter of 2012, the construction of SS 110/10 kV Erzya (Phase 1) was completed. 80 MVA of transformer capacity were commissioned as a result of installing two transformers, 40 MVA each. SS 110/10 kV Erzya is one of the two major main substations in the northwest part of Saransk. The city’s sector serviced by the substation is mainly intended for residential buildings and social and sports infrastructural facilities. Work on the substation construction made it possible to build new production facilities designed to ensure the necessary operating reliability of equipment, reduce the capacity shortage caused by growing loads, and secure an uninterrupted electricity supply for customers.

The project implementation used the project-based management method as part of implementing the Construction Management System for Major Investment Projects.

Technical upgrading and rehabilitation

In the 4th quarter of 2012 work was completed on providing connection to Novokuybyshevsk CHPP generation facilities. The project implementation aims to ensure the delivery of Novokuybyshevsk CHPP-1 capacity after the installation of the 200-MW GTU power unit consisting of three gas turbines, each with unit capacity of 77 MW. The total capacity of the 200-MW GTU is 231 MW.

The main engineering solutions for the implementation of the capital investment project include changing the line routes, building new 35-kV and 110-kV overhead lines and rehabilitating existing lines:

- Dividing OL 110 kV NK-5 with the construction of branch lines to SS 220 kV Novokuybyshevskaya and the creation of two new OL 110 kV Novokuybyshevsk CHPP-1–SS Novokuybyshevskaya and OL 110 kV Novokuybyshevsk CHPP-2–SS Novokuybyshevskaya, branch line length: 4.75 kilometers, wire: AS-240;

- Building a branch line from OL 110 kV Prosvet–Brizol to SS Novokuybyshevskaya, branch line length: 0.18 kilometer, wire: АS-185;

- Building a section of OL 110 kV from tower No. 41 to Switchgear 110 kV Novokuybyshevsk CHPP-1, wire: AS-185, length: 5.326 kilometers, and a section of CL 110 kV;

- Rehabilitating existing OL 110 kV with the replacement of the lightning protection wire, overhead-line accessories, and insulators;

- Building a section of OL 110 kV from tower No. 89 to Switchgear 110 kV SS Kryazhskaya;

- Building an OL 35 kV NK-3 branch line from Main Step-down Substation-1 KNPZ to Switchgear 35 kV SS Kryazh with the construction of a 35-kV overhead cable line consisting of an overhead section (0.17 kilometers) and a cable section (2 x 0.49 kilometer);

- In addition, SS Kryazhskaya (2 cubicles rated 35 kV and 110 kV) will be rehabilitated with the construction of a new cubicle (110 kV) for a new OL 110 kV NK-3 branch line to the substation.

The work completed in 2012 is as follows:

- Construction of concrete towers and metal towers;

- Installation of wires and a lightning protection wire;

- Installation of cables;

- Installation of communication units;

- Construction of cubicles rated 35 kV and 110 kV;

- Construction of 110-kV outdoor switchgear.

23.574 kilometers were commissioned in 2012.

IDGC OF URALS

New construction

In the 4th quarter of 2012, the construction of new SS 110 kV Krasnopolskaya was completed. The total capacity of substation transformers is 80 MVA (2 x 40 MVA) with 2.53-kilometer OL 110 kV. The construction and installation used compact equipment suitable for urban development applications: 110-kV high-voltage bushings with solid insulation; 110-kV disconnecting switches with cable drives operated both remotely and manually. The 110-kV outdoor switchgear has modern circuit breakers with an operating life of at least 40 years. The new substation is of strategic importance to Chelyabinsk. The substation will supply electricity to the promising and fast growing residential areas in Chelyabinsk’s Kurchatovsky District and socially important facilities.

In the 4th quarter of 2012, the construction of new indoor substation 110/6 kV Prirechnaya located in the center of Nizhni Tagil was completed. The commissioned capacity of the facility is 50 MVA and 8.8 kilometers. The substation has two TRDN-25000/110 supply transformers (2 x 25 MVA); 110-kV indoor switchgear is the 4-N configuration (two units with disconnecting switches and a nonautomatic main switch on the side of lines ). The substation is equipped with SF6-insulated space-saving PASS MO switchgear rated 110 kV; 6-kV indoor switchgear consists of 58 D12P cubicles with ВВ/TEL vacuum switches. Work was completed on the construction of a single-circuit branch line from OL 110 kV Tagil–Kislorodnaya to SS Krasny Kamen and the construction of a single-circuit branch line from OL 110 kV Tagil–NTMK-2. Putting the substation into operation made it possible to satisfy the growing electric capacity demand of customers located in Nizhni Tagil, Sverdlovsk Region, which are new residential developments, office buildings, and the city’s social and infrastructural facilities.

In the 4th quarter of 2012, the construction of outdoor SS 110 kV Palniki with OL 110 kV was completed. The total commissioned capacity of the facility is 80 MVA and 2.53 kilometers. The power facility is an outdoor substation fitted with high-technology, up-to-date electrical equipment made by leading Russian and foreign manufacturers. The selection of equipment for SS Palniki took into consideration such characteristics as reliability, explosion safety, fire safety, and environmental safety. The substation construction made it possible to enhance the reliability of the electricity supply for existing customers located in the Dobryanka District and satisfy the increasing electricity demand of the fast growing residential development area in the rural settlement of Krasnosludskoye and the resort area on the bank of the Chusovaya River.

The project implementation used the project-based management method as part of implementing the Construction Management System for Major Investment Projects.

IDGC OF NORTHERN CAUCASUS

New construction

In the 4th quarter of 2012, the construction of SS 110/10 kV Pump Station-4 was completed. 80 MVA of transformer capacity were commissioned. The decision to build the substation was made in reply to the network connection request received by the Stavropolenergo Branch from the Caspian Pipeline Consortium-R for the power supply for electrical installations of Pump Station-4. The substation is fitted with two TRDN-40000/110 U1 transformers, 40 MVA each; VEB-110II*40/2500 UKhLI SF6 switches; RN-SEShch-110/1250UKhL1 disconnecting switches; 10-kV switchgear units are equipped with KRU-SEShch-K-61M, KRU-SEShch-K-63 and other electrical cabinets. The new substation not only will provide network connections for Pump Station-4 electrical installations but also will make it possible to fully secure an electricity supply for new customers located in the Ipatovo District, Stavropol Territory.

The project implementation used the project-based management method as part of implementing the Construction Management System for Major Investment Projects.

IDGC OF SIBERIA

New construction

In the 2nd quarter of 2012, facilities were put into operation under the Investment Project of Implementing the External Electricity Supply to the Raspadskaya Mine and Enhancing the Reliability of Electricity Supply to the Mezhdurechensk District, Kemerovo Region.

Electricity is supplied to the Raspadskaya Mine’s existing facilities from FGC UES’s SS 220 kV Mezhdurechenskaya, put into operation in 1963, and the same substation supplies electricity to Mezhdurechensk. The commissioning of three new 110-kV substations Raspadskaya-4, Raspadskaya-5, and Raspadskaya-6 will completely settle the issue of securing a reliable and uninterrupted power supply for coal producers and ensuring reserve transformer capacity for the development of Mezhdurechensk.

Under the project, five facilities were built:

- OL 110 kV Tom-Usinskaya TPP–Raspadskaya-5-1 with a branch line to SS Raspadskaya-4-6, 52.559 kilometers.

- OL 110 kV Tom-Usinskaya TPP–Raspadskaya-5-2 with a branch line to SS Raspadskaya-4-6, 52.134 kilometers.

- SS 110/6.6/6.3 kV Raspadskaya-4, 80 MVA.

- SS 110/6.6/6.3 kV Raspadskaya-5, 32 MVA.

- SS 110/6.6/6.3 kV Raspadskaya-6, 80 MVA.

In the 4th quarter of 2012, the construction of SS 110/35/10 kV Bystrinskaya and SS 110/35/10 kV Bugdainskaya was completed. The project implementation aims to secure an external electricity supply for the industrial (mining) and transportation infrastructure in the southeast of the Trans-Baikal Territory and provide network connections for GRK Bystrinskoye and Bugdainsky Rudnik. 64 MVA were commissioned (2 x 16 MVA at Bystrinskaya and 2 x 16 MVA at Bugdainskaya).

The above-mentioned facilities were put into operation under Cooperation Agreement No. 48-D/S G-2 of April 30, 2009, between the Trans-Baikal Territory Government and the Company concerning measures to secure a reliable electricity supply and create conditions for providing customers located in the Trans-Baikal Territory with network connections.

IDGC OF SOUTH

Technical upgrading and rehabilitation

In the 4th quarter of 2012, the rehabilitation of SS-110/10 kV Razvilka-2 was completed, with 80 MVA of transformer capacity commissioned as a result of replacing two 16-MVA transformers by two transformers, 40 MVA each. Work on the substation rehabilitation made it possible to secure a reliable electricity supply and satisfy the growing demand of new facilities (TK Akvarel) located in Volgograd.

In the 4th quarter of 2012, as part of providing a network connection for a CPC-R facility, namely construction-in-progress Pump Station-3 of CPC-R under the project to construct SS 110/10 kV Pump Station-3 with adjacent OL 110 kV and the rehabilitation of the adjacent OL 110 kV network, work was completed on the rehabilitation of OL 110 kV SS Elista-Zapadnaya–SS Iki-Burul with OL 110 kV branch lines to SS 110/10 kV Magna and SS Primanychskaya (constructed in 1972) with a total length of 85.2 kilometers. Putting the rehabilitated 110-kV overhead line into operation made it possible to enhance the reliability of the electricity supply for Pump Station-3 and customers located in the Republic of Kalmykia.

Implementing the Construction Management System for Major Investment Projects

Pursuant to Resolution of the Company Management Board No. 81pr/3 of April 14, 2011, the boards of directors of the Company subsidiaries determined that implementing the Construction Management System for Major Investment Projects (CMS) was a priority for their operations. The principal goals of implementing the CMS are as follows:

- Ensure the attainment of targets contained in the capital investment programs of subsidiaries;

- Improve construction management efficiency for major investment projects as related to construction periods, costs, and quality;

- Enhance the transparency of the investment process;

- Optimize the decision-making mechanism for investment project implementation management as related to raising the quality and speed of making decisions on any occurring deviations;

- Standardize the management of specific projects and cut labor costs associated with working out each new project by means of creating a knowledge base related to projects and other issues.

With a view to implementing the CMS, subsidiaries carried out the following measures:

- A regulatory framework was developed with respect to the management of major investment projects;

- 55 pilot projects were singled out from among the capital investment projects of subsidiaries for 2012;

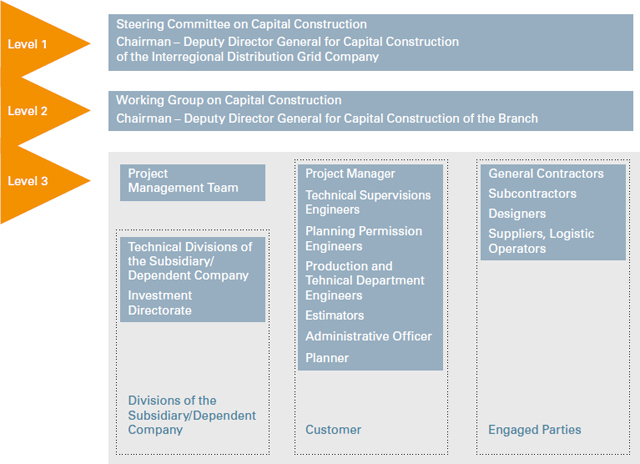

- The structures of a three-level management model were developed for the pilot projects (see the diagram below);

- The Automated Project Management System (APMS) was purchased;

- Training was provided for employees both in the fundamentals of project management and in the use of the APMS;

- The APMS was implemented under the pilot projects.

The APMS includes scheduling and network planning, estimate data integration, and data portal modules. The Data Portal Module ensures the most effective management of communications in projects, including arranging meetings and monitoring the implementation of project-related instructions, preparing reports and downloading project-related documents, viewing network schedules and monitoring the performance of project-related work by means of online photo and video reports.

Out of the 55 pilot projects, 15 were put into operation in 2012; the commissioning of the other facilities is scheduled for later dates.