Technical Audit

The Company continued working in 2012 to organize and conduct technical audits aimed at enhancing the operating reliability and safety of equipment and reducing the risks of process failures and occupational injuries in the electric grid sector.

The development of technical audits in the common internal technical control system of the Company and its subsidiaries aims to improve control procedures in order to obtain complete and reliable information from audits, promptly respond to any negative trends and risks, and take corrective and preventive actions.

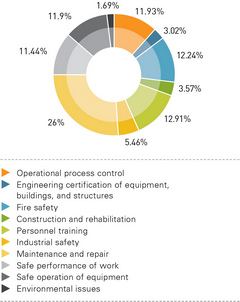

With the involvement of technical inspection units of its subsidiaries, the Company carried out 1,237 scheduled audits in 2012. These included 58 comprehensive audits, 595 audits on specific subjects, and 584 purpose-oriented inspections audits. In total, subsidiaries and their branches and divisions conducted 16,208 audits within the internal technical control system, including inspections of preparations for the heat deficit period and for special working conditions of electric grid facilities (freshets, thunderstorms, and fire hazards).

Based subsidiaries’ audit results showed a positive trend in dealing with the issues of production asset administration as related to the organization of maintenance and repair and to measures to keep equipment in good working order. Overall, the number of deviations found at subsidiaries in this area in 2012 decreased 1.2-fold in the total number of nonconformities.

The audits analyzed the operating efficiency of internal technical control for all elements of the system. Audit opinions contain measures to modify local regulatory documents related to the internal technical control system, improve the quality of audits at all levels, enhance the training of responsible personnel involved in the internal technical control system and their ability to find and identify any existing production risks, and develop and carry out organizational and technical measures to eliminate such risks or reduce them to an acceptable level.

The Company monitored and evaluated the operation of the internal technical control system.

The Company worked to prepare its electric grid companies for the heating season in compliance with the Regulations for Examining the Preparedness of Electricity Industry Entities for Operation in the Heat Deficit Period, approved by the Government Commission on Electricity Supply Security (Federal Headquarters) in 2012, and in accordance with Order No. 290 “On the Results of the 2011/12 Heat Deficit Period and on Organizing Preparations for the 2012/13 Heat Deficit Period” and Order No. 434/339 “On High-Priority Measures to Ensure the Successful Passing of the 2012/13 Heat Deficit Period at Distribution Grid Facilities.”

In the preparatory period, subsidiaries’ branches and divisions underwent a two-stage preliminary audit of their preparedness for the heating season; the audit was carried out by commissions composed of executives, employees, technical inspectors, production supervisors, and occupational safety officers of electric grid companies.

At the first stage, the commissions worked to find adverse trends and risks hampering successful preparations for the heating season and developed measures to eliminate any found risks. At the second stage, the commissions exercised special supervision over redressing the deviations and nonconformities found by the first stage of the preliminary audit. The Company did the monitoring of and made sampling inspections of the work of these commissions by conducting on-site audits.

The preparedness of subsidiaries for the 2012/13 heating season was inspected by a commission of the Ministry of Energy with the participation of representatives of the Company’s divisions. The certificate of preparedness for the 2011/12 heating season was issued to all of the Company’s and their branches.

The division responsible for the organization of supervising progress in subsidiaries’ preparations for the heat deficit period is the Technical Audit Department.

In order to achieve the operating reliability and safety of equipment and provide safe working conditions for personnel, the Company conducted videoconferences with executives of subsidiaries, the Central Examination Commission continued its work, and professional contests (competitions) took place.

Among participants in conference calls were technical managers of the Company and its subsidiaries, FGC UES, their branches, and representatives of the Central Directorate and territorial offices of the Federal Service for Environmental, Technological and Nuclear Supervision of the Russian Federation, discussing high-priority and long-run issues related to preparations for and the passing of the heating season, the improvement of an electricity supply for the regions exposed to high power outage risks, the organization of work on preventing and remedying serious process failures and emergency situations, the organization of work in special periods, the enhancement of the occupational safety management system, and top-priority measures to prevent occupational injuries and making decisions on reducing operational risks of the electric grid sector.

The Company Central Examination Commission worked in accordance with the Personnel Development Rules for Electricity Industry Entities of the Russian Federation approved by Order of the Ministry of Fuel and Energy of the Russian Federation No. 49 of February 19, 2000. In 2012, the Central Examination Commission evaluated executives and employees of the Company; managers of technical inspection, production control, and occupational safety units; chairpersons and members of subsidiaries’ central examination commissions—a total of 43 people. Pre-examination training and evaluation procedures used special software applications.

The Company organized two professional contests in 2012. Pursuant to Resolution of the Government of the Russian Federation No. 1011 of December 7, 2011, “On the ‘Best Professional’ All-Russian Professional Contest,” in accordance with Order of the Ministry of Health and Social Development of the Russian Federation No. 287 of March 2012, “On Holding the ‘Best Professional’ All-Russian Professional Contest,” and in connection with the functions prescribed for the Company as the base organizer of the contest for the “Best Electrician,” Astrakhan-based Astrakhanenergo, a branch of IDGC of South, held a nationwide stage of the professional contest among electrical insulation and overvoltage protection crews of distribution grids. Aside from teams of the Company’s subsidiaries, the regional stage of the contest included teams of Russian regional territorial grid organizations. Professional competitions among repair crews of the Company’s subsidiaries and FGC UES’s branches took place at Sochi-based Sochi Electricity Networks, a branch of Kubanenergo. The goals of these contests are to improve and evaluate the professional qualifications of personnel, enhance the quality of work and the safety of equipment maintenance, disseminate advanced working techniques among energy companies, and shape a positive public opinion on worker labor and the attractiveness of training in worker occupations.

With the annual growth in the capital investment programs of subsidiaries, in order to reduce the risks associated with the construction, rehabilitation, and technical upgrading of facilities, the Company’s technical audit in the common controlling system involves a simultaneous concerted effort as part of control procedures, including procedures organized in the financial audit area.